Once you have that step practiced, turn the grinder on.

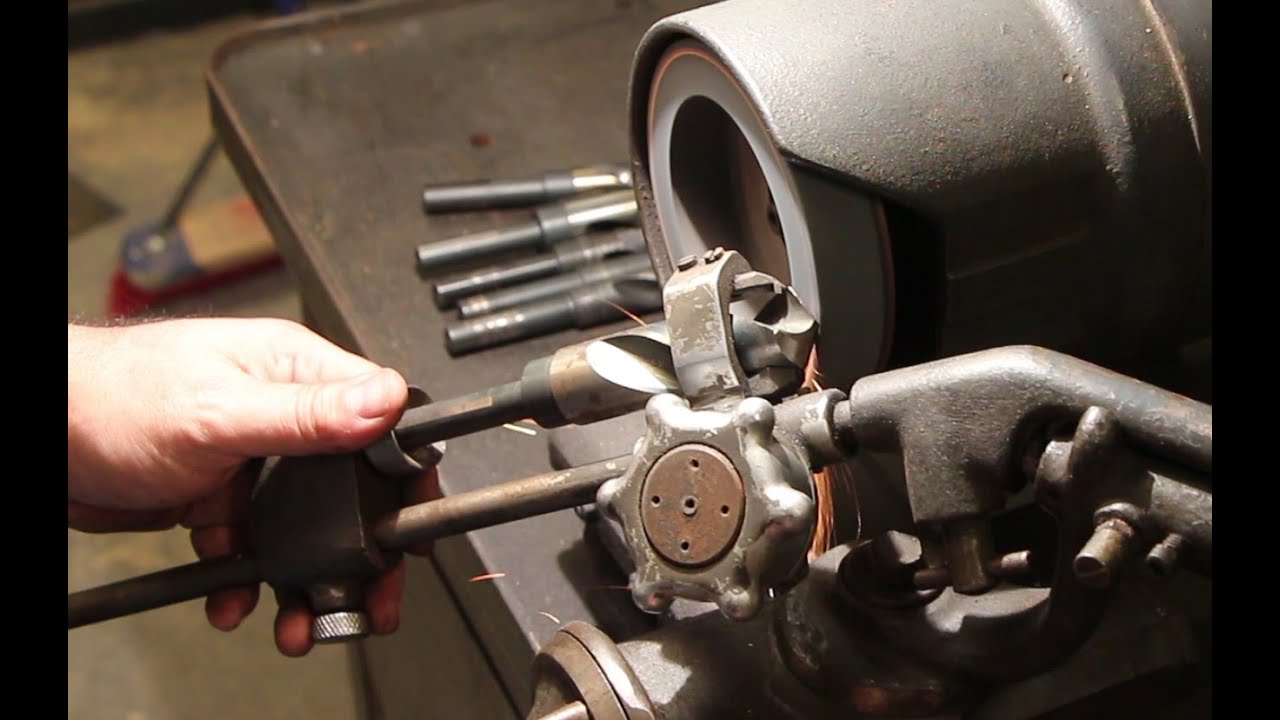

The other hand should be closer to the cutting edge and used for both supporting and maintaining the cutting angle. One hand should be on the shank for both turning the bit and maintaining the angle. With the grinder turned off and the wheel not rotating, practice holding the bit in your hands with the cutting edge facing the side of the wheel. Flying pieces of the grinding wheel, spinning at high RPM's is dangerous! Wear eye and face protection at all times. Do not push the bit into the wheel too hard. To accomplish this requires some time, patients and practice. The correct method is to exactly duplicate the existing angles. The method and steps required and machines needed is below. I doubt a hand held Dremel drill motor will do the task. After drilling an inch or two, pull the bit back out, and you should see chips flying.Īnd that’s all there is to it! With this clever technique, you won’t have to rush out and spend needless money on new drill bits.Hello MJMcGreal and Welcome to our Do-It-Yourself Web Site and my Sharpening forum. Push the bit down into the wood piece just enough for it to “bite.” The bit should easily bite into the wood without force. If it passes this initial test, chuck the bit into your drill and give it a whirl. If it’s properly sharpened, it will begin to make a hole with very little pressure. Test your new and improved drill bit by holding the tip against a piece of scrap wood and turning it clockwise by hand. If not, make grinding adjustments until the two sides center up. The two cutting edges should meet to form a center point. When both edges are sharpened, check to make sure they’re the same width by looking at the drill bit end-on.If this is done evenly, the bit will perform better.

Don’t worry about maintaining the original curvature. Slowly bring the bit in contact with the wheel, keeping it as straight as possible without rotating or turning it.You only want to remove as much metal as is needed to clean up and sharpen the edge. Hold the drill bit so that the cutting end is parallel to the surface of the grinding wheel.Be very careful about how you position your hands and wear safety glasses. WARNING: your hands will be near a dangerous sharpening device! Gloves run the risk of getting caught in the machine and pulling you in – so don’t wear them. It’s not a perfect method, but if done right, this technique will save you money and time, getting you back into action fast.Ģ) a bench grinder or belt sander Safety Precautions This article demonstrates the old-school way of sharpening by hand. Keep in mind that sharpening your drill bits can be a rather tricky process. If there’s a project coming up that requires some drill work and your drill bits are getting a little worn, but you’re not too keen on trekking out to the local hardware store, then read on! There’s actually a simple little technique you can do – whether your drill bits are chipped, broken, or just plain worn out – that will transform them back (or almost back) to their original sharpened luster! Sharpening Your Drill Bit We may earn commission from our brand partners when purchasing products through our links. She has a wide range of knowledge and, because of this, has been able to contribute to a variety of different genres, including article and blog writing.Īs an editor, she has polished and perfected an array of pieces for diverse readerships and audiences. Anna Ryan is a writer, copywriter and editor.

0 kommentar(er)

0 kommentar(er)